Stand up pouch is widely used in our daily life. We can see many food like coffee, nuts, snack, beef jery, protein power, flour packed by stand up pouch with zipper. So today, we write this article to introduce stand up pouch.

First we talk about the material. The first kind is kraft stand up pouches. From the name, we know there is paper material in the pouch. Actually there are at least three layers material: kraft paper/VMPET/PE or MOPP/kraft paper/VMPET/PE. Thickness of unprinted paper stand up pouch is usually 150mic. And for printed kraft paper stand up pouch, thickness can be 160mic. The second kind is plastic stand up pouches. Some customer like matte effect, So there is matte stand up pouch. Some customer prefer glossy effect, so there is glossy stand up pouch.

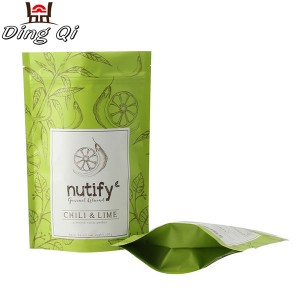

Second we talk about the detail of stand up pouch. There is bottom gusset on the pouch(bottom). There is zipper on the top of the pouch, which can let pouches reusable. If you want hanger hole, we can add on the top of the pouch for free. There are two kind of hang hole, one is Round hang hole. The other kind is Euro hang hole.

Third thing, we want to talk about the printing. Pouches use Gravure printing technology. So there are CMYK, white color and spot color. Each color need one plate to print. So if you have 6 colors, need 6 plate to print.

Finally, I want talked about MOQ. MOQ is 5000pieces per artwork or size. Why 5000pieces, not 4000pieces, 3000pieces or even 1000pieces? The process of making pouch is very complicated. There are three main process: 1) printing, laminating with different layer of material, cuting. Each step need large of roll film to switch the machine. Pouch cant be made one by one. Even you want only one bag, the process are the same. So the labor cost and switch match material are the same. So the total cost of make one bag isnt much different from 5000pieces pouch making.

Post time: Apr-25-2019